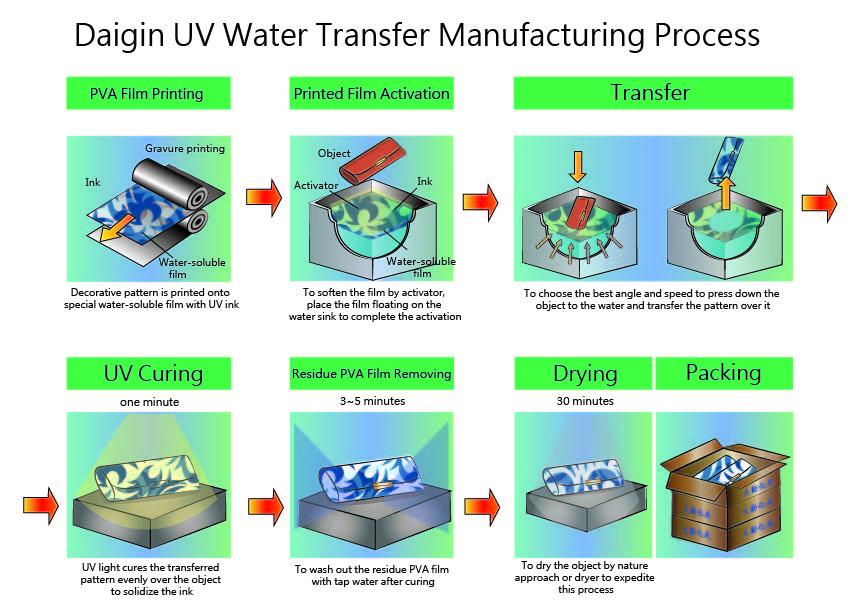

1. Activation -- to soften the film by activator, then makes some cut around the edge, then place the film floating on the water sink to complete the activation;graphic、water temperature and humidity will determine how soon the film is activated;at the very beginning, the film will be wrinkling and smoothening afterward, and ready for transfer.

2. Transfer -- to well clean the object while film is activated, and then choose the best angle and speed to press down the object to the water and transfer the pattern over it.

3. UV curing -- UV light cures the transferred pattern evenly over the object to solidize the ink, basically, curing each part by 30~60 seconds, the graphics and lines could be at the risk of peeling off if the curing is not adequate.

4. Residue PVA film removing -- to wash out the residue PVA film with tap water after curing.

5. Drying -- to dry the object by nature approach or dryer to expedite this process, then the finished product is available.

Manufacturing process flow: